¶ 1. Mount Fuses Near the Battery Terminal

A fuse is there to protect the wire, have it as close as possible to the battery terminal to protect the circuit beyond the fuse. If wires rub through and short circuit inside the loom or other circuits, then they are protected beyond the fuse.

In some jurisdictions (regulatory bodies) there are specific maximum lengths allowed and requirements for fusing on all wires directed attached to a battery. This applies to both the power-carrying circuits and the balancing sensor wires. This is a good idea even where it is not a requirement for safety.

We suggest fuses be placed typically less than 10-15 cm (8 in) from a battery terminal — the closer the better.

ALWAYS place the fuse near the battery. It can save your project as an unprotected fault will be less likely to occur.

¶ 2. Ceramic DC-Rated Fuses are Preferable

We typically recommend hooking up your typical 22-26 AWG hook-up cable to an in-line 3A fuse (preferably ceramic sand-filled) to extinguish the DC arc.

Typical fuse holders of 5 x 20 mm or 6.32 x 32 mm ( diameter / length) are suitable for low voltage circuits.

SHOP: Set of 18 Fuses and Fuse Holders

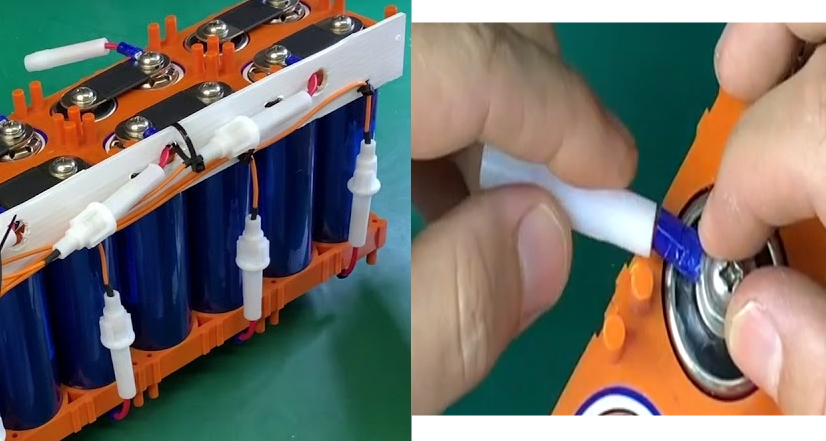

¶ 3. Tinned Multi-Stranded Wire

¶ Multi-Stranded VS. Solid-Core

- Multi-stranded wires are far more tolerant to mechanical vibration, movement, and flexibility, which means it is going to last longer and are less likely, in their lifetime, to fail.

- Solid-Core, whilst an excellent strong conductor, is less flexible and can easily break with repeated movement. If they break it can be hard to detect intermittent faults when flexed in certain directions due to the insulation holding the conductors together.

¶ Tinned Versus Raw Copper

Most wires have raw copper under the insulation which is fine, however tinned copper will add extra protection to corrosion at the exposed terminals. It is all about durability, exposed wires at the connectors are tinned to make them last.

¶ 4. Smallest Cable Size Possible

For balancing wires they ideally use a 26 AWG rating cable, it will blow at 10 Amps (i.e. self-fuse) and we choose to use this size cable on our LongMons and BlockMons for that reason.

If you are interested in looking at the fuse rating of different wire gauges/sizes, here is one example: American Wire Gauge. (Note that there are other sources out there.)

We frequently see photos of DIY projects running balancing cables with medium-duty 16 AWG wire from their batteries without fusing (according to the charts it will handle 398 A for 1 second).

Do not only consider the continuous power rating of the wire but also the rating of when it will fuse and fail.

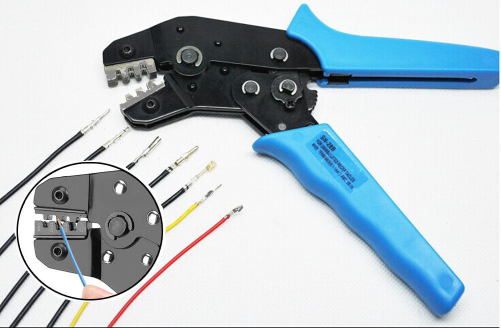

¶ 5. Use Crimping Tools when Necessary

Wires need to be crimped, do not use pliers or your fingers, when working the proper crimping tools allow a tight joining of wires which keeps them solid.

If not crimped properly, the cables can fatigue over a period of time and the connection will fail. It takes but a moment to carefully crimp your cable wires which gives you solid mechanical and electrical connections and allows them to last long into the life of your project.

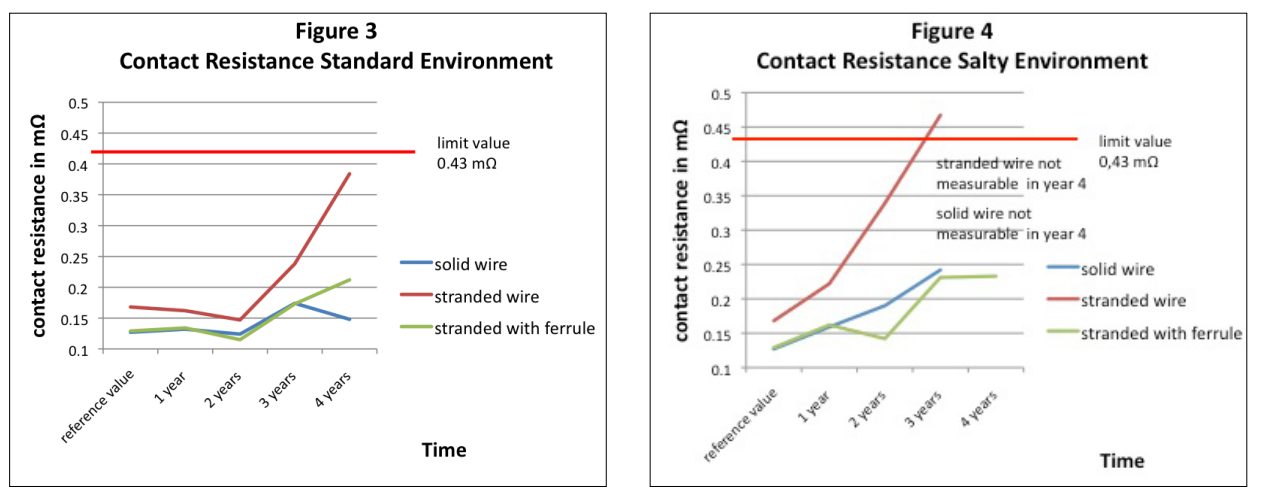

¶ 6. Ferrules Ensure Better Connection at Terminal Screws

Make sure you crimp your wires for efficiency and longer-lasting cable life for your project. Ferrules help ensure that you have good connections to terminals ensuring mechanical durability and preventing the strands from being pitched.

¶ Ferrule or Not to Ferrule?

Read more about what is a ferrule and why stranded wires with ferrules perform much better than without them: TO FERRULE OR NOT TO FERRULE?

¶ 7. Adopt Connectors that Shield the Wire

Always consider the risks of accidental short circuits. Multi-core connectors have a lot of pins in close proximity making it very important in your selection and pin assignment.

Consider sufficient air gaps (typically referred to as pitch) and those with separators between pins.

Connectors that fully enclose the pins for both the Male and Female housings are ideal as if dropped reduce the chance of a fault occurring.

¶ 8. Colour Coding of Wires to Prevent Confusion

Colour Coding can make troubleshooting easier and avoid mistakes

Each colour can be used for a specific identification or purpose, best to adopt typical colour-coding conventions and avoid mixing them up:

- BLACK is Negative - SN on our WatchMon Supervisor terminal strip

- RED is Positive - SP on our WatchMon Supervisor terminal strip.

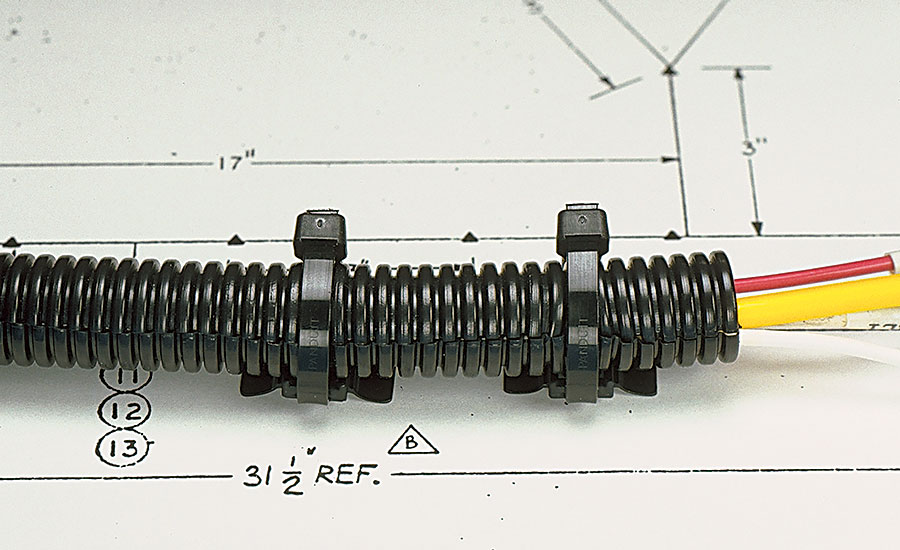

¶ 9. Add extra housing or conduit, especially outside enclosures

Whenever combining multiple wires together, always consider putting them into a split-core conduit or some form of secondary protection or shielding so that they cannot be punctured.

Attach cable ties around cables and anchor at enough intervals to ensure that they are properly mounted to structures, preventing them from catching or getting tangled.

¶ 10. Use cable Glands or Grommets when passing through enclosures

Any time a wire passes through an enclosure, cabinet, or box, it needs to have protection with Cable Glands to prevent insulation from being pinched, causing a fault.

¶ Typical questions we get asked

¶ 1. What size fuse to use?

Depending on the wiring gauge and the power required on the circuit, for balancing cables we typically recommend 22-26 AWG hook-up wire with an in-line fuse of 3 Amps, ceramic (preferably sand-filled) so that it can extinguish the DC arc.

¶ 2. Can I just fuse the positive wire?

Every wire that is attached to the battery needs to be fused as any core has the potential to fail. Not just the positive but also the negative and the balancing/sensor wires.

¶ 3. Can I use a different cable, or a CAT6 LAN cable instead?

It is OK to use the CAT5 network pair (This has 4 twisted pairs. Make sure to use multi-strand patch lead, not the in-wall solid core variant.) *Shielding is generally not required.