WARNING: Please remember that basic knowledge of electronic circuits and batteries is needed to build a battery pack and attach a BMS. The Batrium BMS is not a plug-and-play device.

¶ Why Do I Need a Starter Kit?

We sell starter kits to help customers procure the right components and avoid any missing parts.

The raw components are also available for purchase by existing customers who need additional items for their current projects.

¶ Which Starter Kit Do I Get

Reminder: We cannot choose for you and cannot advise about battery design. You may need to get extra help from someone to advise you on how to manage the unique issues to keep them safe for electrical cabling fusing and mechanical management depending on the configuration you have chosen. We can only give you advice on what is available and suitable for your project.

To get started, the first thing needed is a Starter Kit. This guideline will have the basics to help you begin your home pack:

¶ All starter kits come with a WatchMon supervisor.

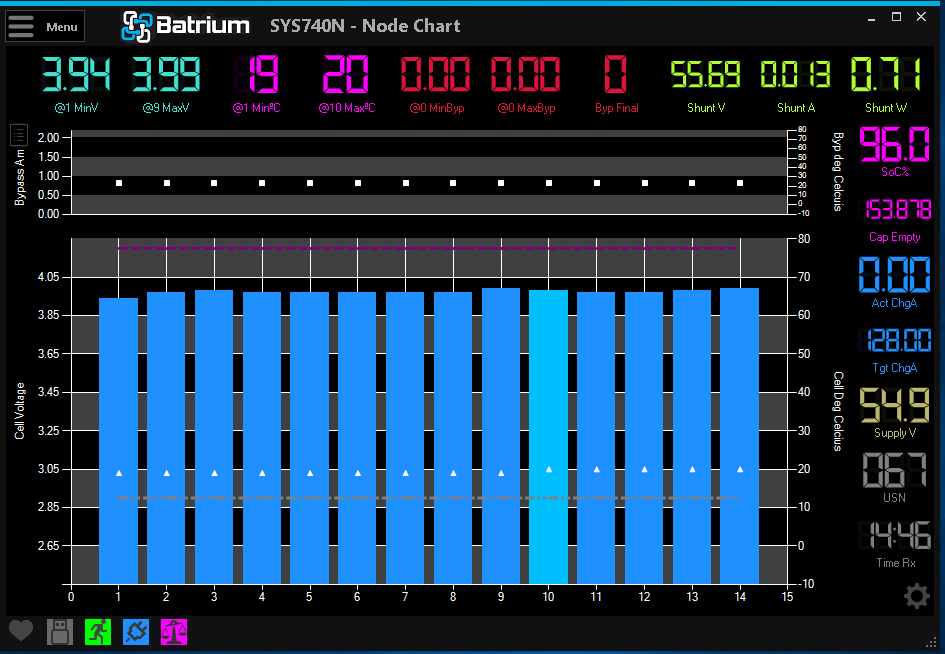

WatchMonCORE - This is the brain of the system. It is configurable to your requirements and can monitor between 1 and 250 cells. The key function of the supervisor is to monitor the cells.

When the WatchMon detects that the cells are outside their limits, it will attempt to notify the connected remote system with a warning to alter operation. Ideally, warnings bring the battery back to its operating limits. If the condition escalates, the supervisor will trigger a critical event and attempt to interrupt the battery with a contactor/circuit breaker.

If managing multiple battery bank/s with a single WatchMonCORE, they must be of the same nominal voltage (48V, 24V etc) and cell chemistry (LiFePO4, Li-Ion, LTO etc), this is so the targets and balancing can be the same for all cells/banks.

There is also a 1:1 relationship between an inverter and a WatchMonCORE supervisor. If you want to have the supervisor run multiple independent banks to independent inverters at different states and/or chemistry, you will need separate supervisors to control each inverter with their instructions for charge and discharge instructions.

If your battery has a shared loom, then it is should not be used with WatchMonCORE.

To decide which items you require for your starter kit, you need to ask yourself a few questions:

¶ 1. Which cell monitor is best for me?

Do you need a Central (CellMate-K9)or an Individual cell monitor (LongMons, BlockMons, & LeafMons)?

- CellMate-K9 is our newest cell monitor and it is centralised — this means that the cell monitoring has generally simpler wiring. One CellMate-K9 allows between 3-16 cells to be monitored for systems from 12V, 24V or 48V systems. Multiple can be adopted in a chain with up to 20 modules with a maximum of 250 unique cells.

- Meanwhile, LongMons, BlockMons and LeafMons are individual cell monitors, which means that each cell has a separate monitoring module. Each cell monitor measures between 2.2V and 5V.

Here's an article describing the main differences and similarities between the different cell monitors: Comparison of Cell Monitors

¶ 2. How many cell monitors do I need?

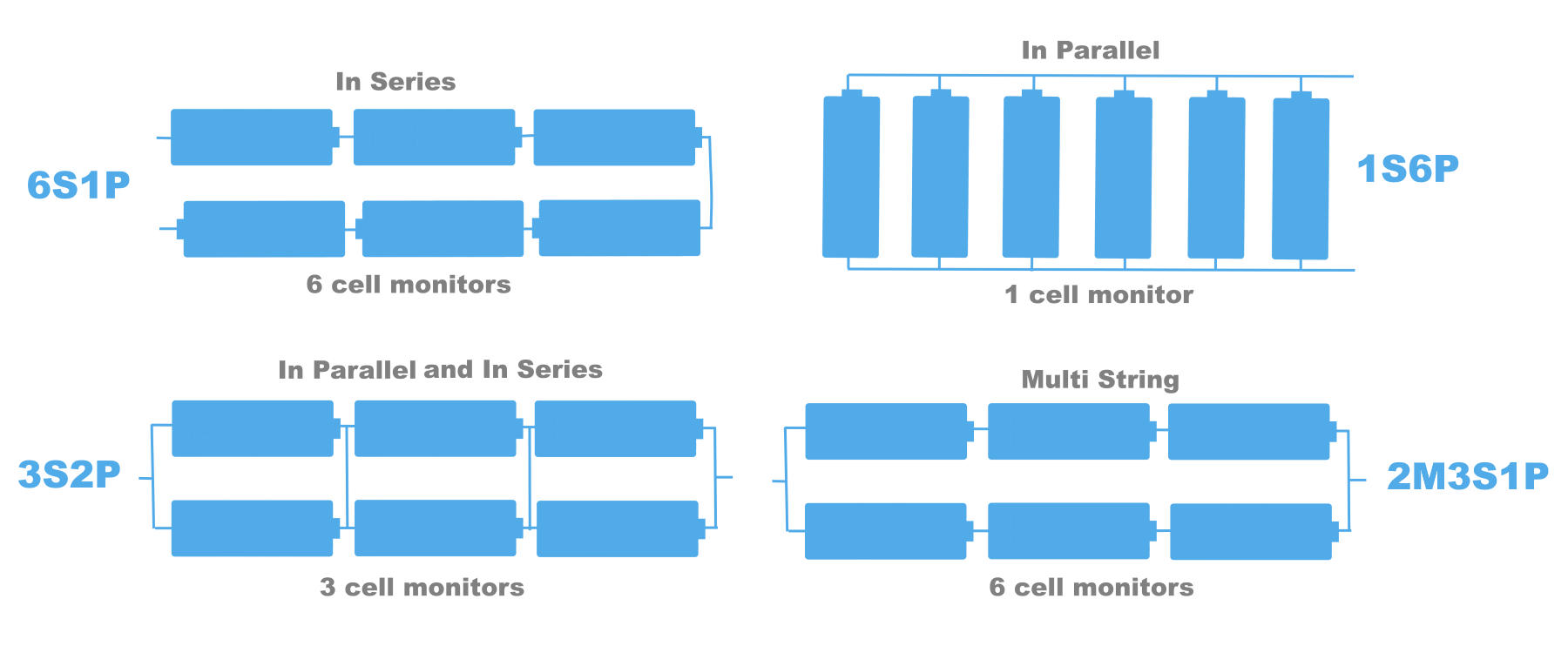

The diagram below shows a battery with all combinations having the same capacity of 6 times a single cell.

¶ 6S1P

Higher voltage (x6) with a current limit of single-cell rating (needs 6 cell monitors)

¶ 1S6P

Voltage of single-cell but 6 times the current rating A and Ah values (needs 1 cell monitor)

¶ 3S2P

Voltage of 3 times cell but double (x2) the current rating A and Ah values (needs 3 cell monitors)

¶ 2M3S1P

(Confusingly referred to as 3S2P) voltage of 3 times cell but double (x2) the current rating A and Ah values, however, needs 6 cell monitors.

Notes:

- Each cell or group of cells in a series need to be monitored.

- Cells wired in parallel should all be at the same voltage therefore only 1 monitor is needed.

- If using parallel banks of cells, these cells are measured separately and hence need extra monitors (Multi-string).

For reference and guide, read our multi-string configuration article: Multiple Cell Monitors or "Multi-String " Configuration: Adding Batteries in Parallel to the Same WatchMon Supervisor

¶ 3. Do I need the State of Charge?

*Optional but recommended

The Batrium Shuntmon is a SOC% monitor that can give you an idea of the state of the battery which isn't possible using voltage alone.

Our logic will work without this information but if connected via CANbus to an inverter that does need this information it may be essential rather than just useful.

¶ 4. Do I need the Expansion Board or is the WatchMonCORE sufficient?

The purpose of the Expansion board is to connect to external devices such as a fan, heater, circuit breaker, etc.

The Expansion Board also contains both relays and SSR (Solid State Relays) to switch outputs as well as a couple of isolated inputs. The WatchMonCORE has only one built-in relay.

Therefore, the Expansion Board is needed if you want to switch more than one output.

It's best to know your own requirements and what you wish to connect, to decide if this is needed for you.

¶ 5. Connecting an inverter/charger via CANbus?

All our WatchMon are capable of CANbus messaging.

It is also important to consider the inverter communication to ensure that the BMS can advise the inverter/charger to ramp down the charging rate to be more gentle to the batteries when close to full, or disable discharge or reduce its rate. The interface is specific to each inverter and the amount of information able to be shared varies greatly depending on the complexity of the inverter. In all cases, a SOC% sensor is required if connecting the inverter this way. Inverters Compatible via CANbus

The products from Victron for example have extra functionality where the BMS sends extra details about the battery state for their VRM integrations through a tailored CANbus profile.

If your inverter is capable of CANbus but not one that we have tested, please refer to the article: What if my inverter isn't on your compatible list?

*Note that not all other inverters have the same CANbus profile, they all have their own unique arrangement of messages and functionality.

¶ 6. Do I need a circuit breaker?

*Optional but recommended

For safety, a circuit breaker with a remote trip linked to the BMS is always a good idea to ensure that the supervisor can disconnect the battery from the inverter or charger when there is a critical event.