¶ What are Series / Parallel / Multi-String Battery Banks?

Choosing a configuration is harder than choosing our BMS.

When choosing your configuration, it is important to consider how the BMS needs to monitor the cells.

- Series

- Parallel

- Multi-string

Note: Energy from the battery is always sourced from the system of the lowest impedance. This is why the strongest battery string provides the power first and when it becomes depleted less than another string, that one then takes over. In a parallel set, they work in unison to balance each other out. If or when there are different strings involved, this idea works somewhat similar.

This is the reason why people talk about making sure that the wiring of the battery busbars needs to be of equal impedance, which some refer to as length.

Know that there is a lot more to this and you can read more about these things online. If you are unsure, you may need to get extra help from someone to advise you on how to manage the unique issues to keep them safe for electrical cabling fusing and mechanical management depending on the configuration you have chosen.

¶ SAMPLE WIRING GUIDES

¶ IN SERIES

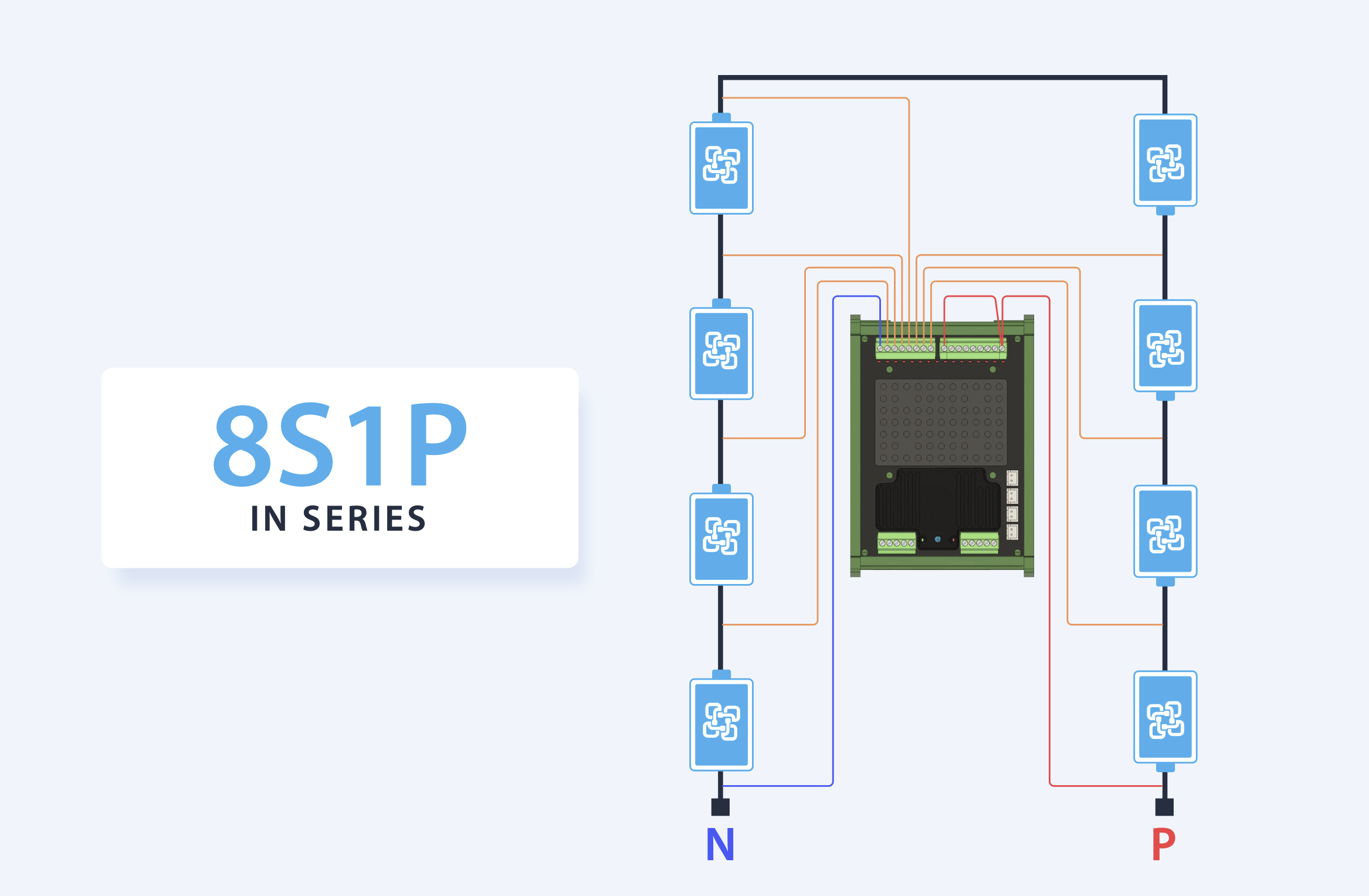

¶ 8S1P IN SERIES

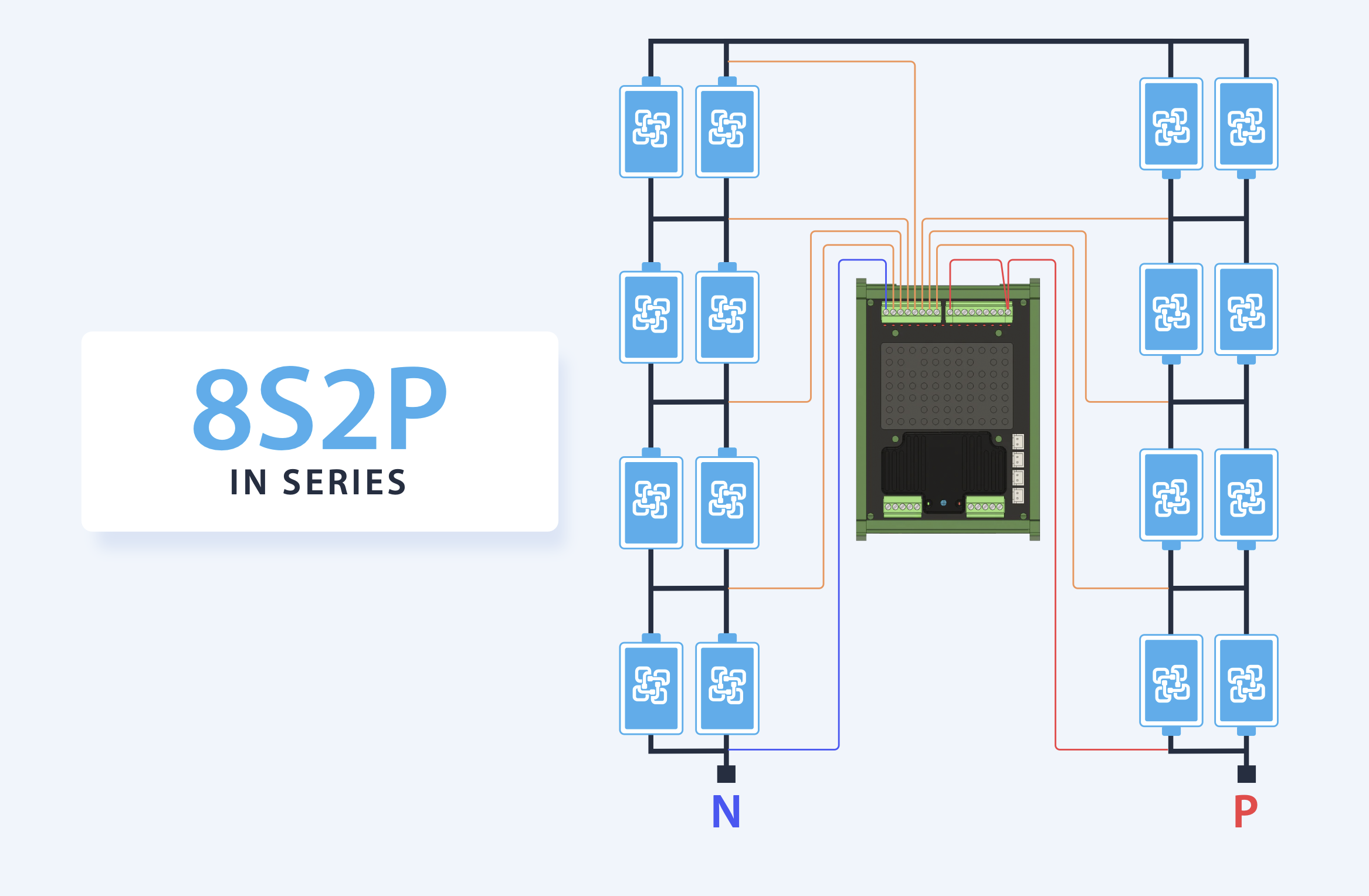

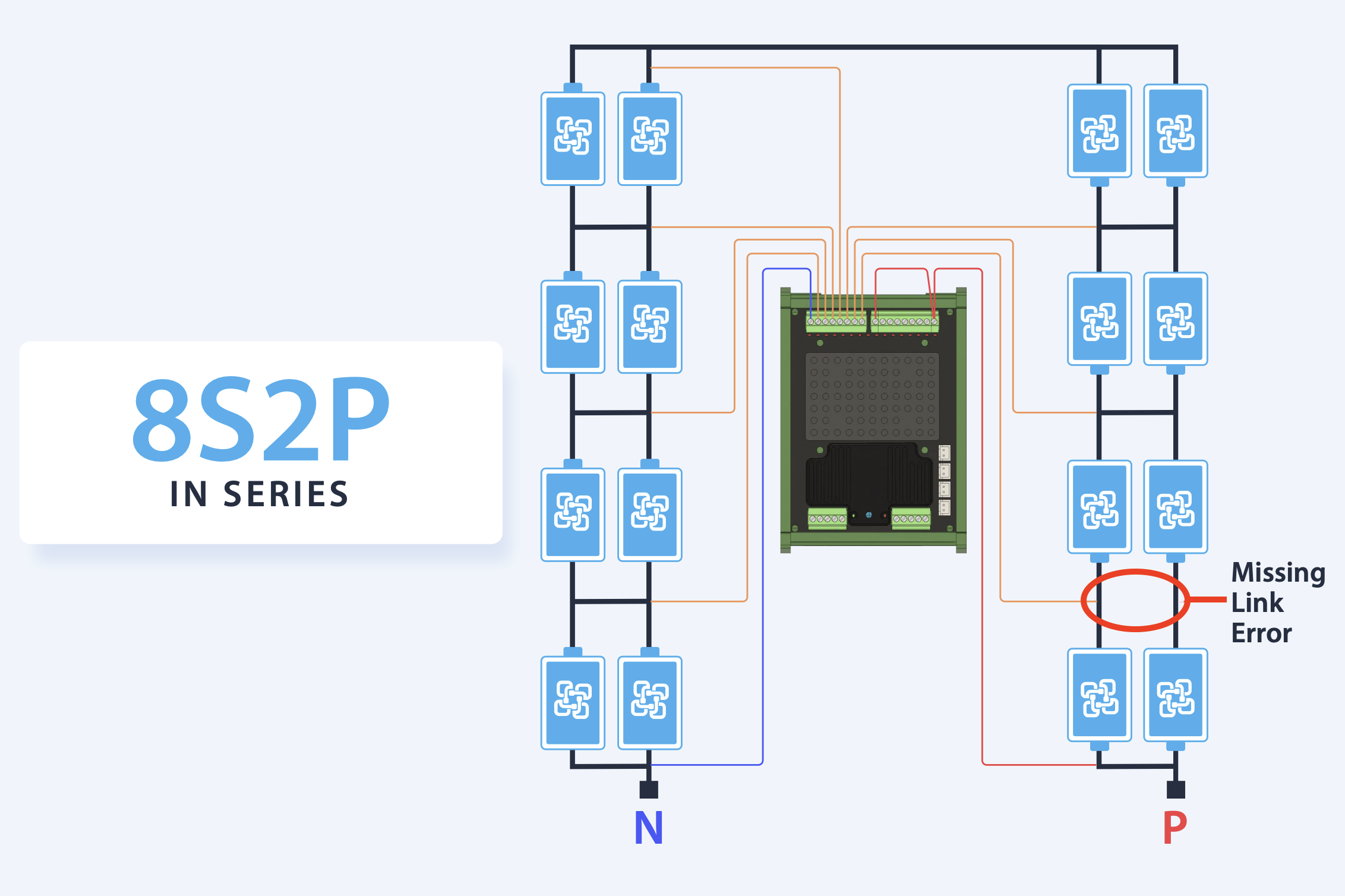

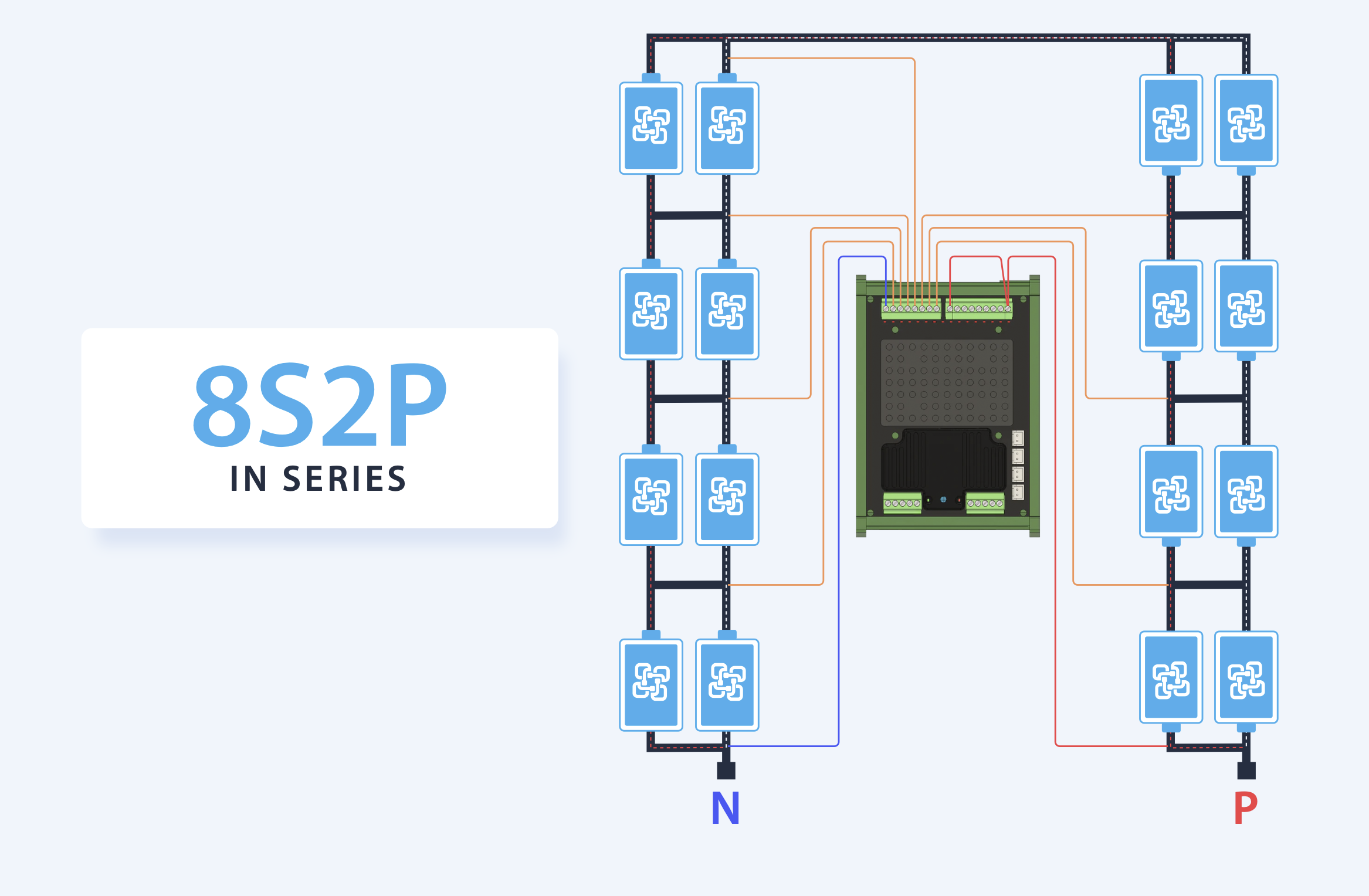

¶ 8S2P IN SERIES

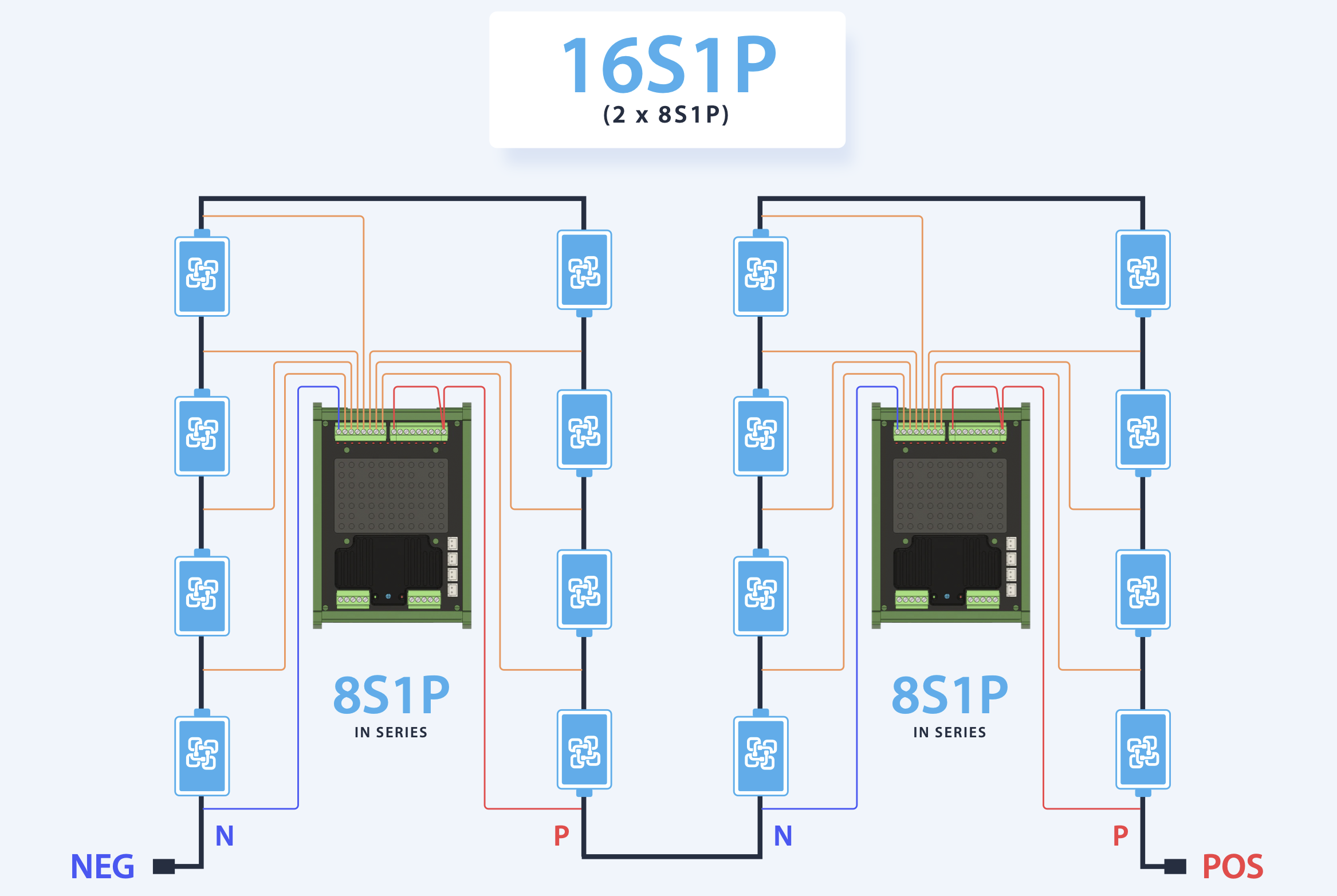

When doing your installation, make sure the power path busbars (black lines) are equal in length and that there are no missing links on your installation, as shown on the photos below.

¶ MULTI-STRING

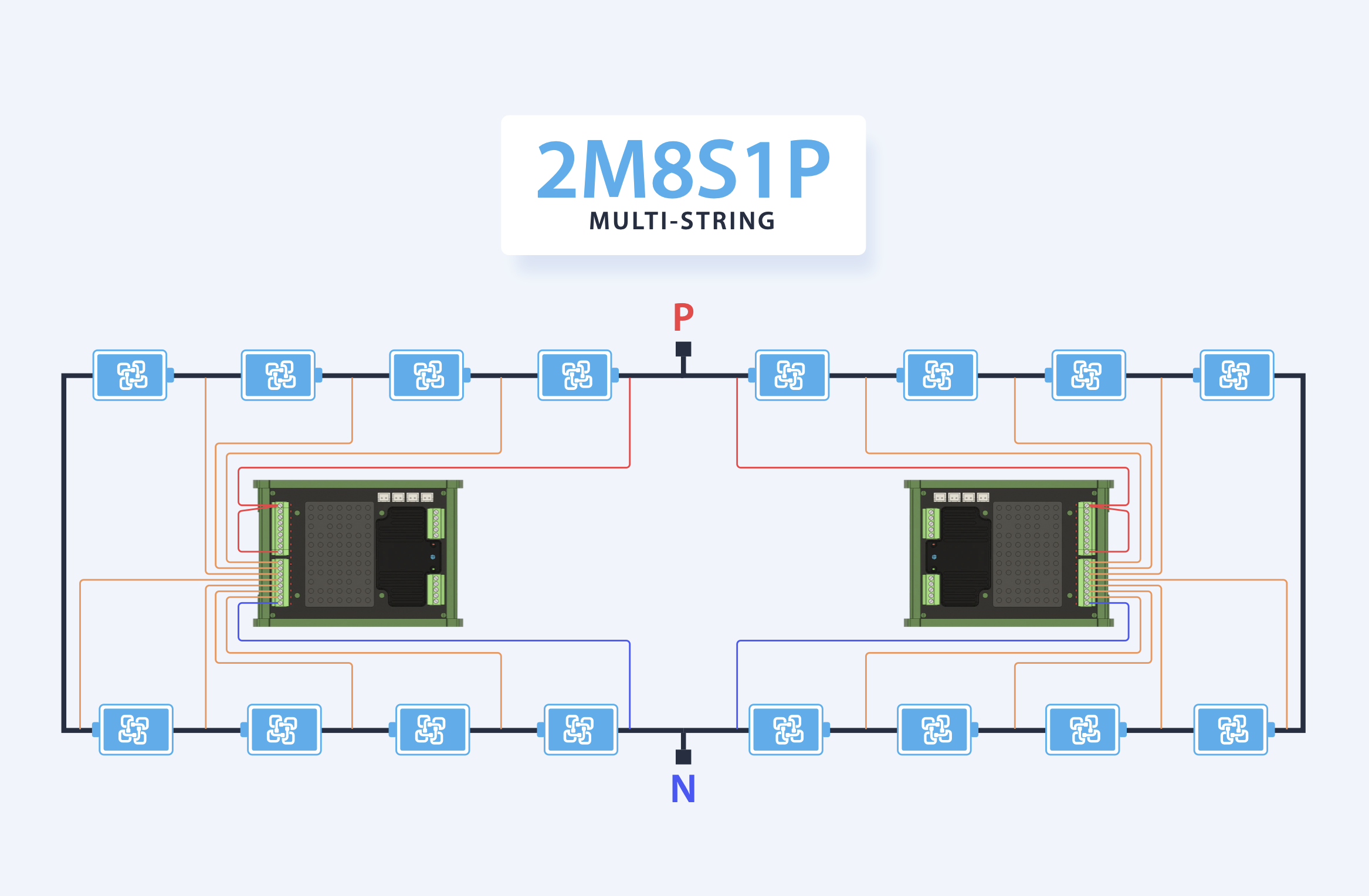

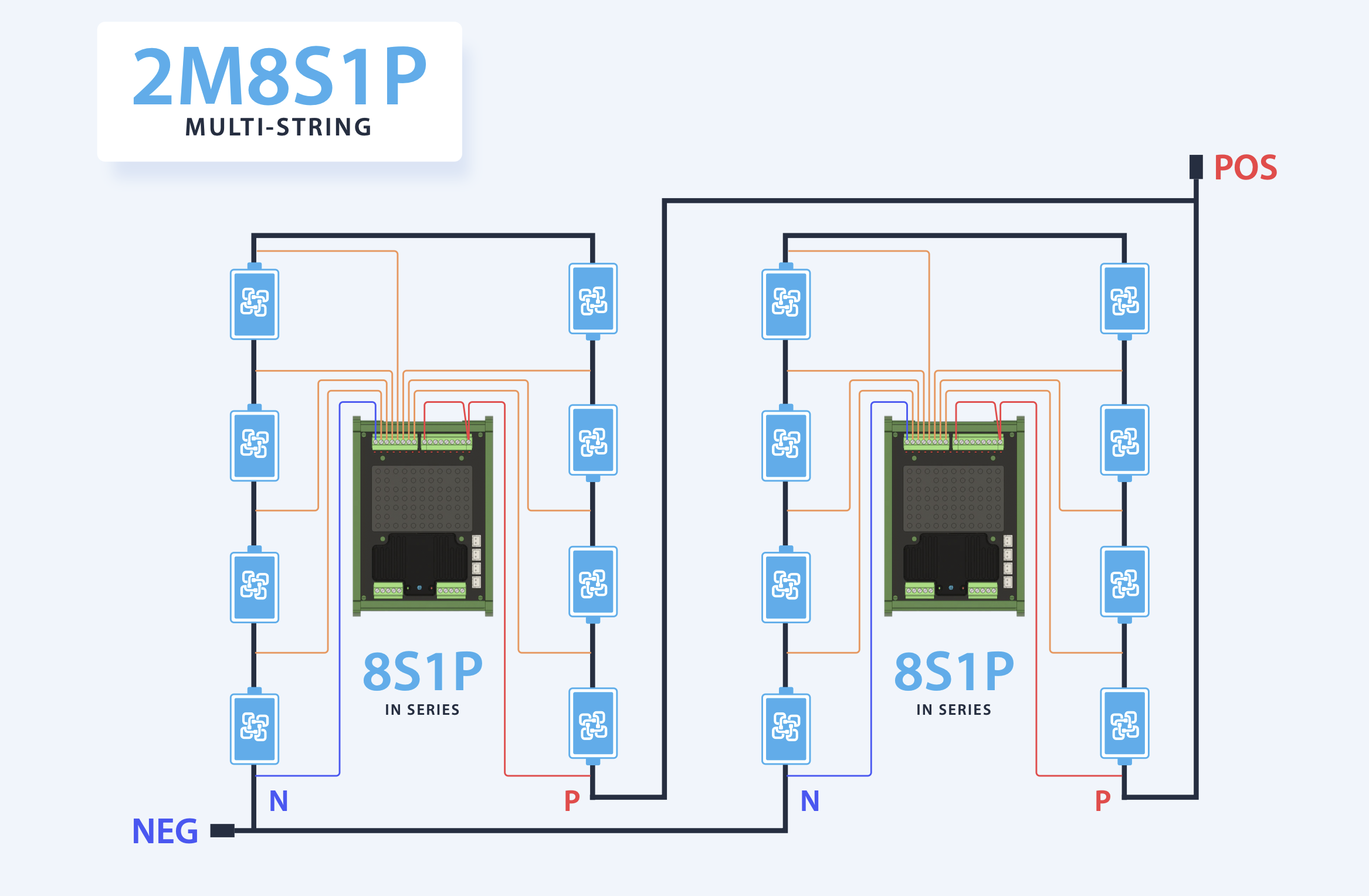

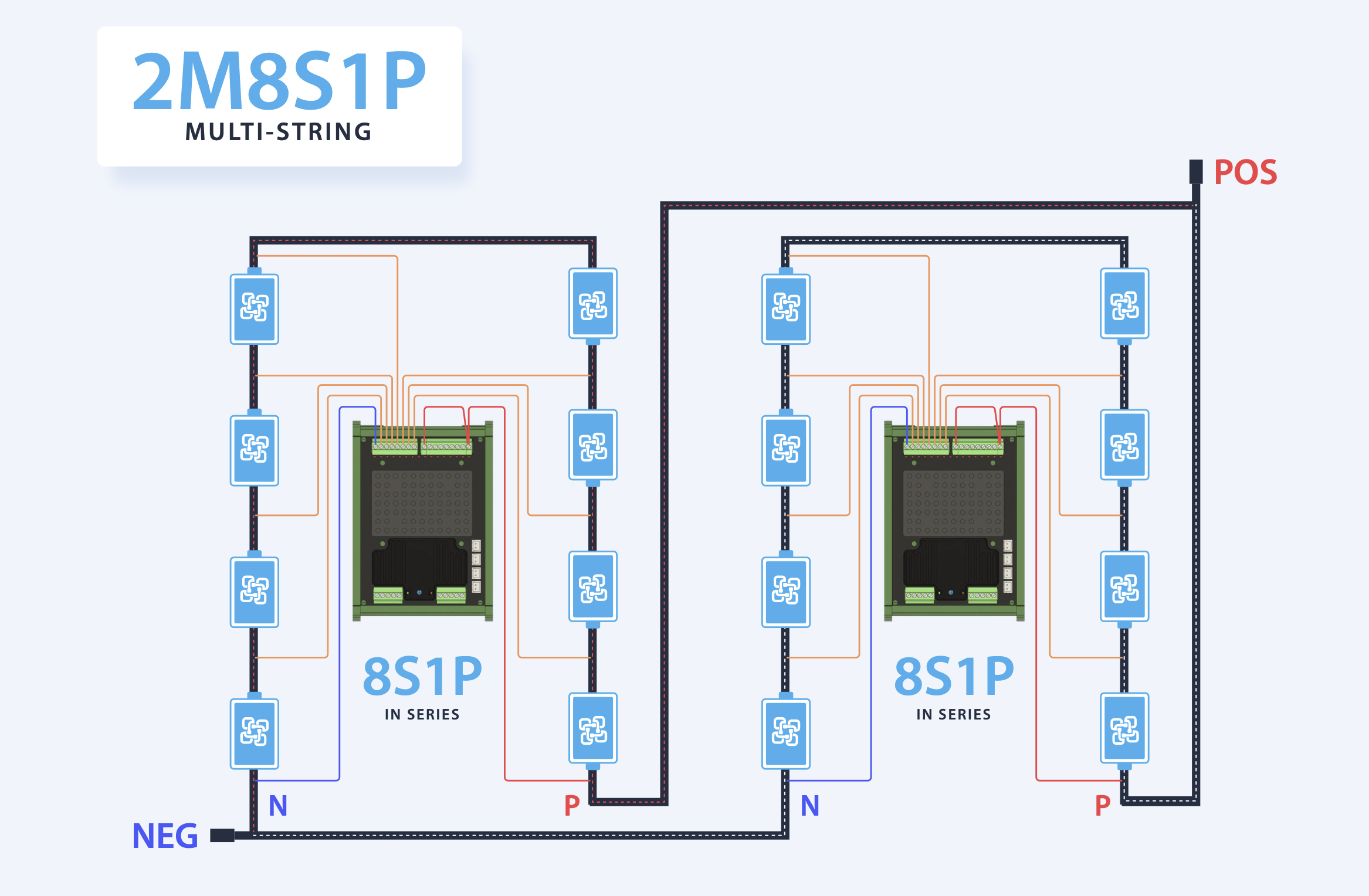

¶ 2M8S1P MULTI-STRING

Here's another layout for the 2M8S1P Multi-String wiring:

¶ 16S1P (2 x 8S1P)

Notes:

- Each cell or group of cells in a series needs to be monitored.

- Cells wired in parallel should all be at the same voltage therefore only 1 monitor is needed.

- If using parallel banks of cells, these cells are measured separately and hence need extra monitors (Multi-string).

¶ Why Multi-String?

This is a question asked regularly.

First, it will require more BMS components and hence will be more expensive. It is generally only adopted when the bank of cells has been repurposed from another application.

Usually, they are already assembled into a configuration that cannot be changed and hence this approach is adopted.

Alternatively, when adding more capacity at a later date, a multi-string can be used to increase the battery bank with more cells without adjusting the original pack.

¶ Why Parallel First and Then Put in Series?

It is a much simpler and cheaper option with fewer BMS components.

The links between the parallel cells need to be large enough to ensure that there are no voltage differences and rated to handle the full current of the string of cells.

There are safety risks if you're attempting this with only small balancing wires (NOT recommended) as this has consequences that a trained battery technician will understand.

¶ Multi-String Configuration: Adding Batteries in Parallel to the Same WatchMon Supervisor

The Batrium system is very flexible.

The cell monitor network is optoisolated, which means you can technically start the daisy chain network wherever you like. There is no correct/wrong order where you can start wiring the pack. The first cell on the daisy chain will be the first blue bar or cell #1 on the screen. The last cell on the network chain will be shown as the last blue bar on the screen.

Batteries are normally wired starting from cell #1, being the most negative cell on the pack. And then work the way up to the most positive cell.

If you are constantly adding more cell monitors and batteries to an existing system, you don't necessarily have to re-configure the whole battery pack. It is easier to just keep on linking the new cell monitors from the last cell monitor on the daisy chain network.

¶ Toolkit Configuration

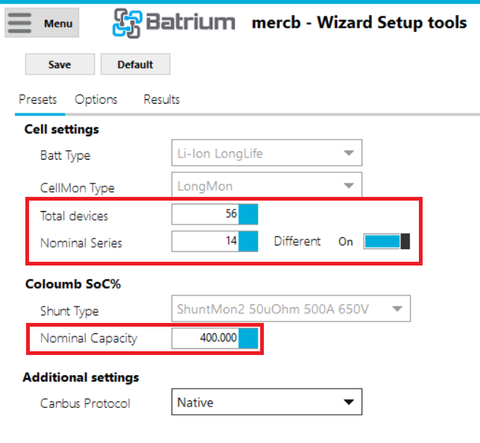

Example: If you have 14 packs with one LongMon each and you decide to expand and want to add more packs in parallel. You will need to keep the 14s nominal but you now need to tell the system that you have 56 devices (LongMons) on the daisy chain network.

There are two easy step-by-step procedures:

- Setting up a new multi-cell monitor system

- Adding more cell monitors to an existing configured system

¶ For New Systems

Open the WatchMon Toolkit software and navigate to the Tools Menu.

- Open the Wizard Setup.

- Add the Total of Devices you are using, in this example 56.

Select "Different ON".

This enables you to select the number of **"Nominal series", in this example 14.

The "Nominal Total Capacity" should be updated as you add more cells to your pack. If you have 100Ah cells and you have 4 in parallel, you should write 400Ah.

Click "Save".

Go back to the main monitoring screen chart, you will see 56 blue bars, as in this example.

¶ Adding More Cell Monitors to an Existing Configuration

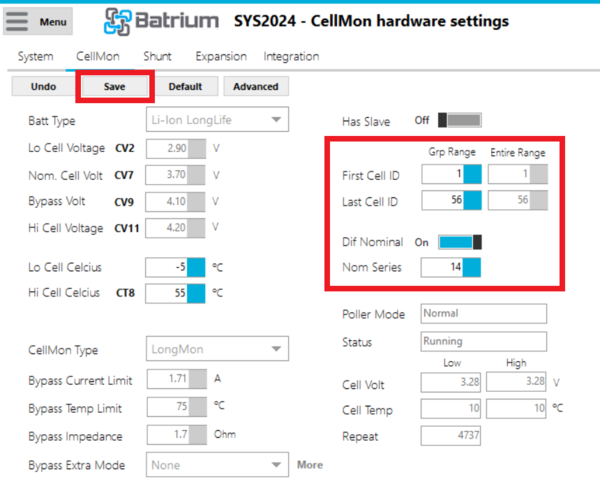

Open the WatchMon Toolkit software and navigate to CellMon Settings.

- On CellMon Tab, click the Edit Button and you should see the screen below.

Add the total of devices (LongMons) you are using, in this example 56. Select "Dif Nomina" ON. This enables you to select the number of "Nominal series", in this example 14.

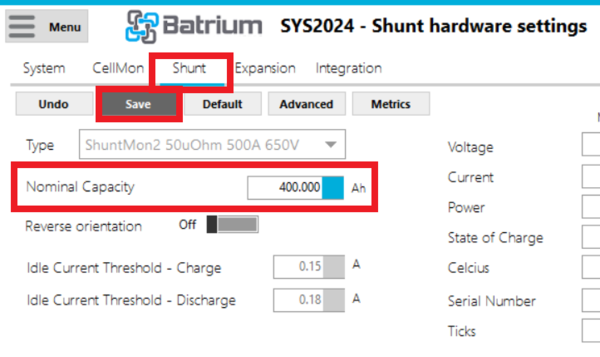

Select the Shunt Settings Tab. Click the Edit Button on Shunt Settings Screen.

- The "Nominal Total Capacity" should be updated as you add more cells to your pack. If you have 100Ah cells and you have 4 in parallel, you should write 400Ah.

¶ Identifying Cell Monitors

Regardless of the order, you wire the Cells Monitors on the chain, you can easily identify each CellMon, Cell or Pack using this procedure: How to Identify a Specific CellMon using the LED.

Despite being easy to identify the Cell Monitors using the LEDs, labelling the packs also helps identification.